Product Center

From forged blanks to precision finished products, comprehensive automotive chassis parts manufacturing solutions

Stabilizer Links

Made from high-strength alloy steel forgings with precision CNC machining and anti-corrosion surface treatment. Features excellent fatigue resistance and corrosion protection, effectively improving vehicle stability. Suitable for passenger cars and commercial vehicles with OEM customization support.

Outer Tie Rod Ends

Precision forged Housing combined with high-precision ball stud ensures steering system accuracy and durability. Features special seal design to prevent dust and moisture intrusion. Passes rigorous fatigue testing and wear resistance verification for harsh operating conditions.

Inner Tie Rod Ends

Specially designed for steering rack inner connections with special threaded structure and high-strength ball joint design. Precision heat treatment ensures reliability under high-load conditions. Equipped with dust boots and special grease for extended service life.

Suspension Ball Joints

Load-bearing suspension ball joints with integrated forged design, capable of supporting full vehicle weight and various road impacts. Ball housing uses special materials, ball stud undergoes precision grinding and surface strengthening. High-performance seals ensure long-term maintenance-free operation.

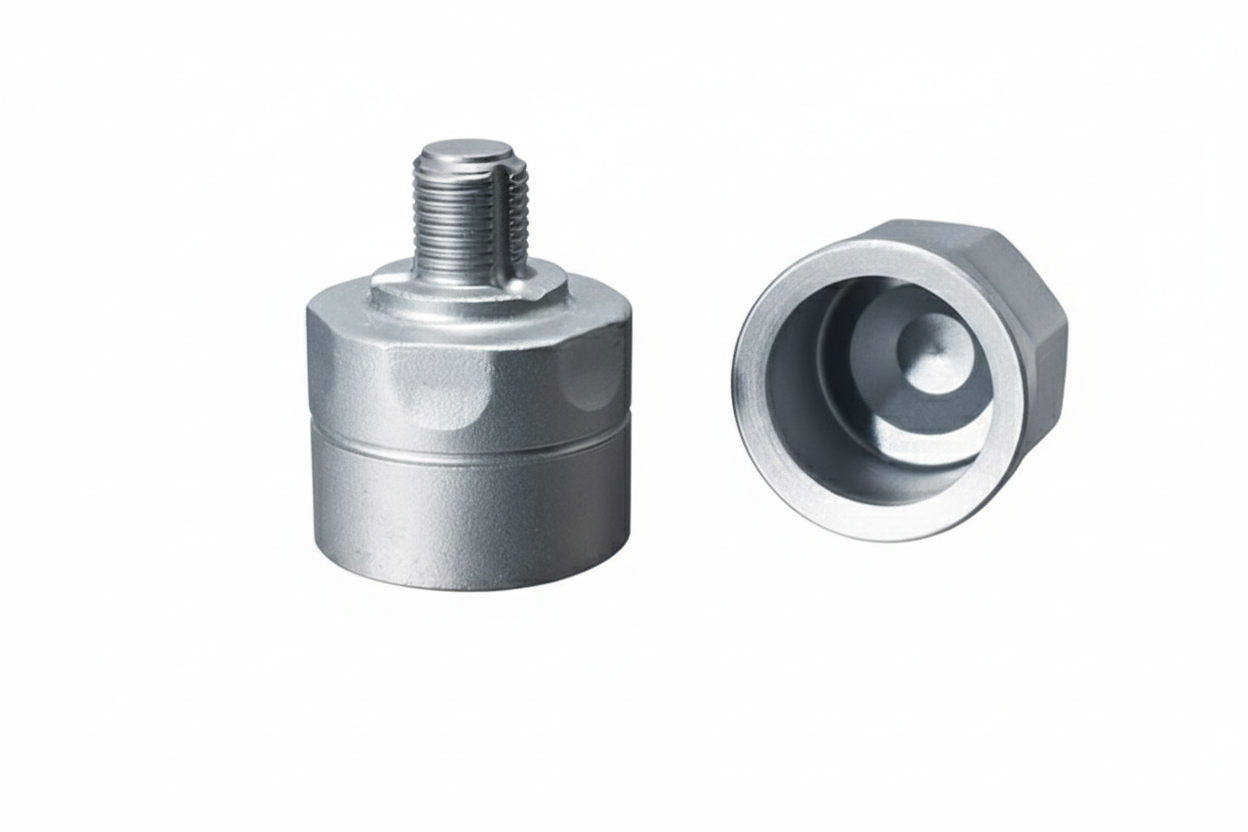

Ball Stud Components

Precision-engineered ball studs with superior strength and durability. Manufactured using advanced forging and CNC machining processes to ensure perfect spherical geometry and surface finish. Heat-treated for optimal hardness and wear resistance. Compatible with various automotive suspension and steering systems with customizable thread specifications.

Stabilizer Link Socket

Precision-engineered stabilizer link sockets with integrated ball joints and protective boots. Our advanced forging and CNC machining processes ensure optimal durability and performance. Each socket undergoes rigorous testing for load capacity and corrosion resistance to meet OEM specifications.

Heat Treated Components

Complete heat treatment equipment providing quenching & tempering, hardening, tempering, and carburizing processes. Strict control of heating temperature, holding time, and cooling rate ensures products meet design mechanical properties. Every batch undergoes hardness testing and metallographic analysis.

Surface Treated Parts

Equipped with high-temperature cleaning and automatic anti-rust coating systems, providing zinc plating, powder coating, electrophoresis, and anodizing. Strictly follows automotive industry standards ensuring excellent corrosion resistance and appearance quality. Supports customer-specified colors and coating thickness.

Threaded Components

Professional threading equipment providing internal and external thread machining services. Supports metric, imperial, and unified thread standards. High-precision threading tools and specialized inspection equipment ensure thread accuracy and surface quality. Thread strengthening treatment available per customer requirements.

Ball Pins

High-precision ball pins made from special alloy steel materials with precision turning and grinding. Ball surface roundness and surface roughness strictly controlled ensuring perfect fit with ball socket. Carburized and quenched for high surface hardness and tough core meeting long-term service requirements.

Rubber Bushings

Bushing products manufactured from high-quality nitrile rubber or polyurethane materials. Features excellent elasticity, wear resistance, and aging resistance. Precision molded with high dimensional accuracy and tight fit with metal components. Supports different hardness and color customization for various operating conditions.

Rubber Bushings

Bushing products manufactured from high-quality nitrile rubber or polyurethane materials. Features excellent elasticity, wear resistance, and aging resistance. Precision molded with high dimensional accuracy and tight fit with metal components. Supports different hardness and color customization for various operating conditions.

Rubber Bushings

Bushing products manufactured from high-quality nitrile rubber or polyurethane materials. Features excellent elasticity, wear resistance, and aging resistance. Precision molded with high dimensional accuracy and tight fit with metal components. Supports different hardness and color customization for various operating conditions.

Rubber Bushings

Bushing products manufactured from high-quality nitrile rubber or polyurethane materials. Features excellent elasticity, wear resistance, and aging resistance. Precision molded with high dimensional accuracy and tight fit with metal components. Supports different hardness and color customization for various operating conditions.

Rubber Bushings

Bushing products manufactured from high-quality nitrile rubber or polyurethane materials. Features excellent elasticity, wear resistance, and aging resistance. Precision molded with high dimensional accuracy and tight fit with metal components. Supports different hardness and color customization for various operating conditions.