Rigorous Quality Standards

"We believe in 'Doing it right the first time' and continuous improvement to ensure full customer satisfaction. By tracking performance and Management by Objectives, we make sure every strategy is based on real data."

Comprehensive quality control system from raw material inspection to final product delivery. Every component undergoes rigorous testing to ensure world-class quality standards.

Laboratory Testing Equipment

Advanced testing and analysis equipment for comprehensive quality control from microscopic structure to macroscopic performance

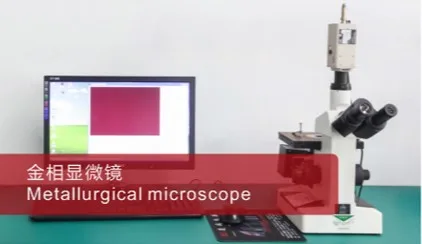

Metallographic Microscopy

Microstructure analysis and grain size measurement for material characterization

Magnetic Particle Testing

Non-destructive testing for surface and near-surface defect detection

Hardness Testing

Precise hardness measurement using Rockwell, Brinell, and Vickers methods

Profile Projector

Optical measurement for dimensional inspection and geometric analysis

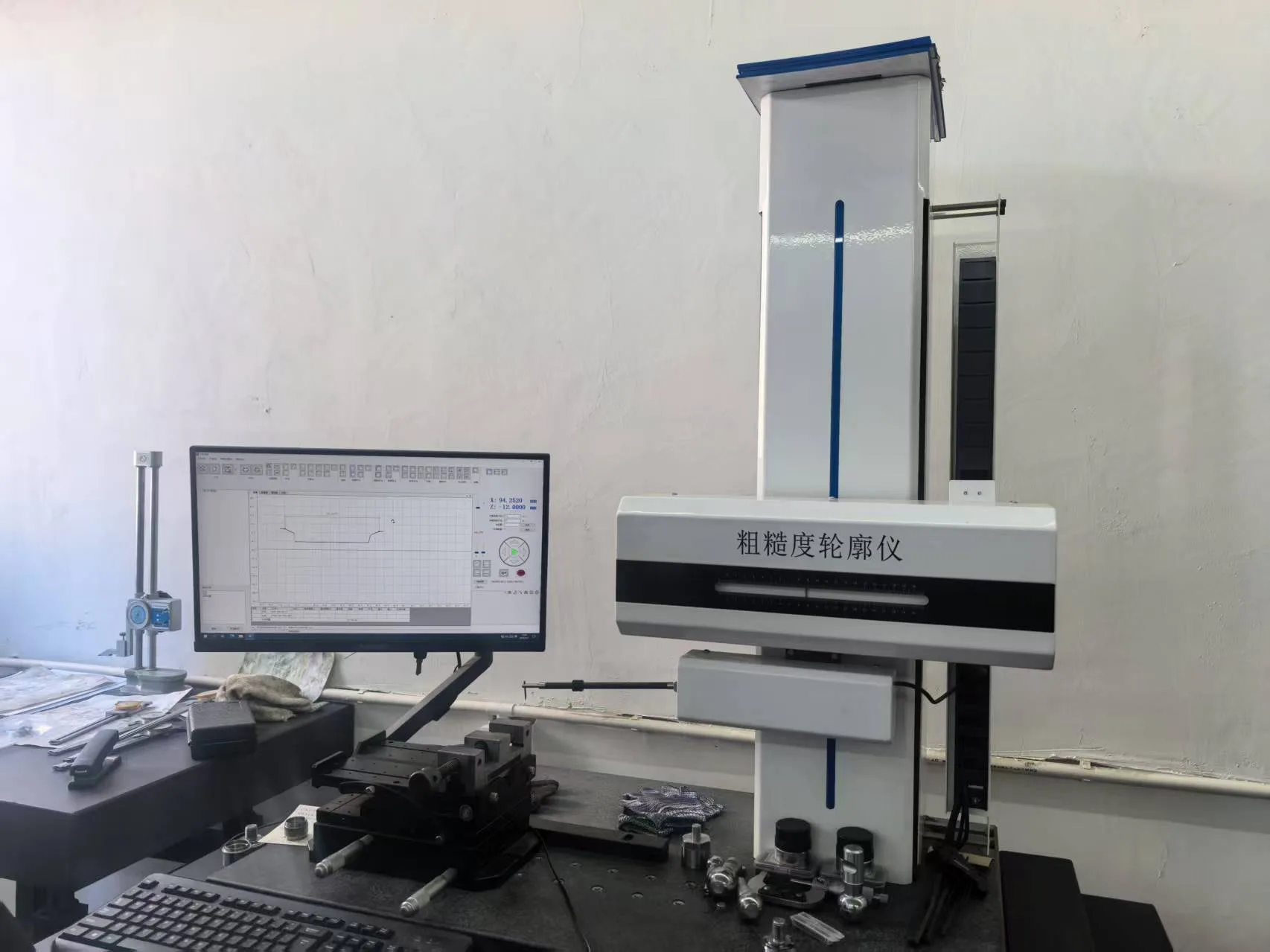

Surface Profilometer

Surface roughness and contour measurement for quality control

Torque Testing Machine

Precise torque measurement and mechanical strength validation

Runout Gauge

Rotational accuracy measurement and concentricity inspection

3D Coordinate Measuring

High-precision 3D dimensional measurement and geometric tolerance verification

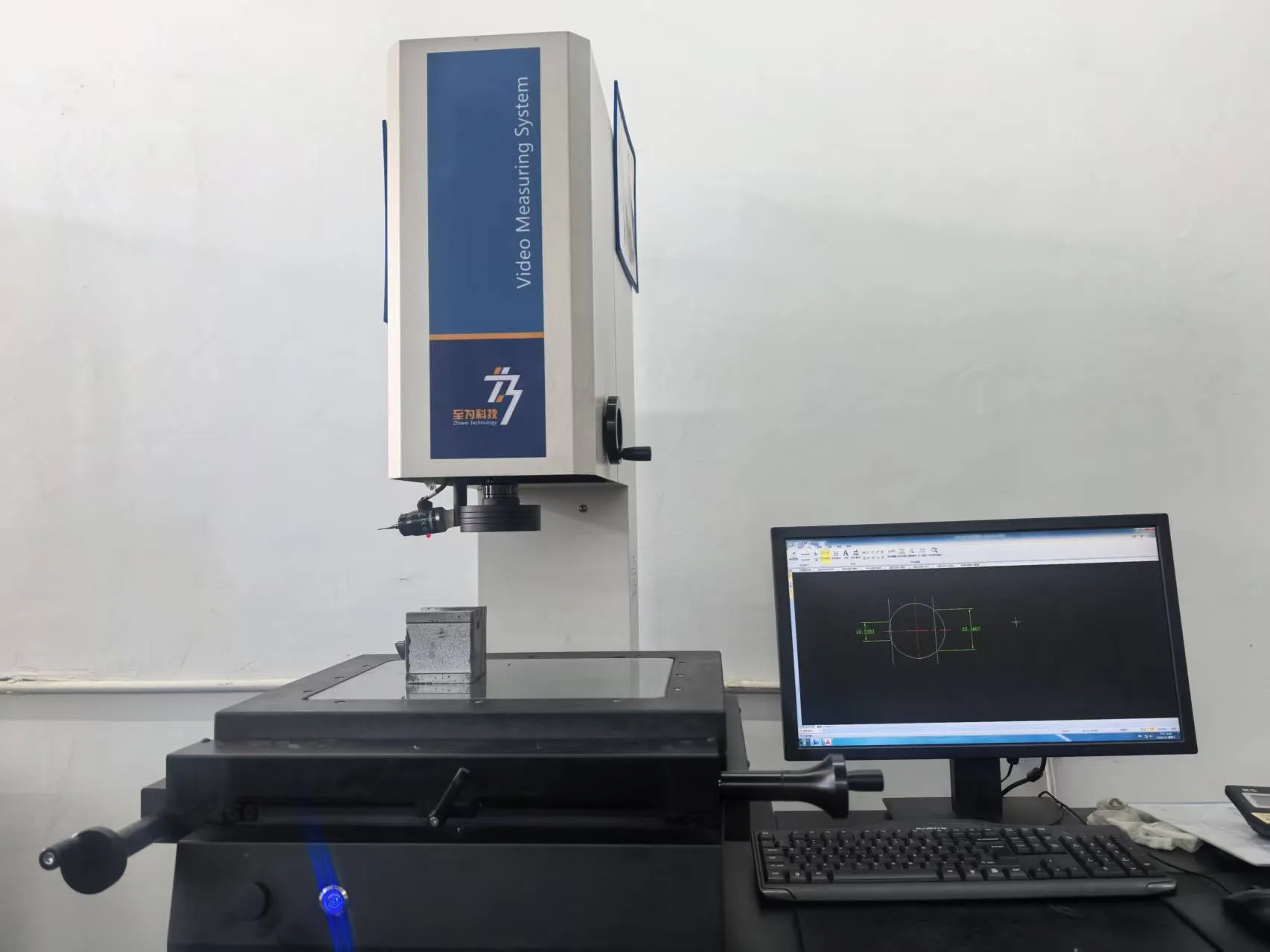

One-Touch Flash Measuring

Rapid multi-dimensional measurement with instant results and analysis

Professional Testing Equipment Configuration

Laboratory Specifications

Quality Assurance

Quality Control Process

Establish a comprehensive quality control system with strict quality control at every stage from raw materials to finished product delivery

Raw Material Inspection

Chemical Composition Analysis

Mechanical Property Testing

Appearance Quality Check

Blank Process Control

Dimension Monitoring

Parameter Control

First Article Inspection

Machining Inspection

Dimensional Accuracy Testing

Surface Roughness

Geometric Tolerance Measurement

Assembly Quality Control

Assembly Torque Control

Functional Performance Testing

Appearance Quality Check

Final Product Inspection

Final Quality Confirmation

Packaging Quality Check

Certificate Issuance

Statistical Process Control

Utilize SPC statistical techniques to monitor production processes and promptly identify and correct quality deviations

- Real-time Control Chart Monitoring

- Process Capability Analysis

- Trend Warning Mechanism

Total Quality Management

Establish a quality management system with full employee participation to ensure quality responsibility implementation at every stage

- Quality Responsibility System

- Continuous Improvement Mechanism

- Employee Training System

Quality Traceability System

Establish complete quality traceability records to achieve full-chain traceability from raw materials to end users

- Batch Management System

- Quality Archive Filing

- Rapid Problem Localization